Product Consulting Cart

Your list is empty now

Add Products

Total : 0Unit

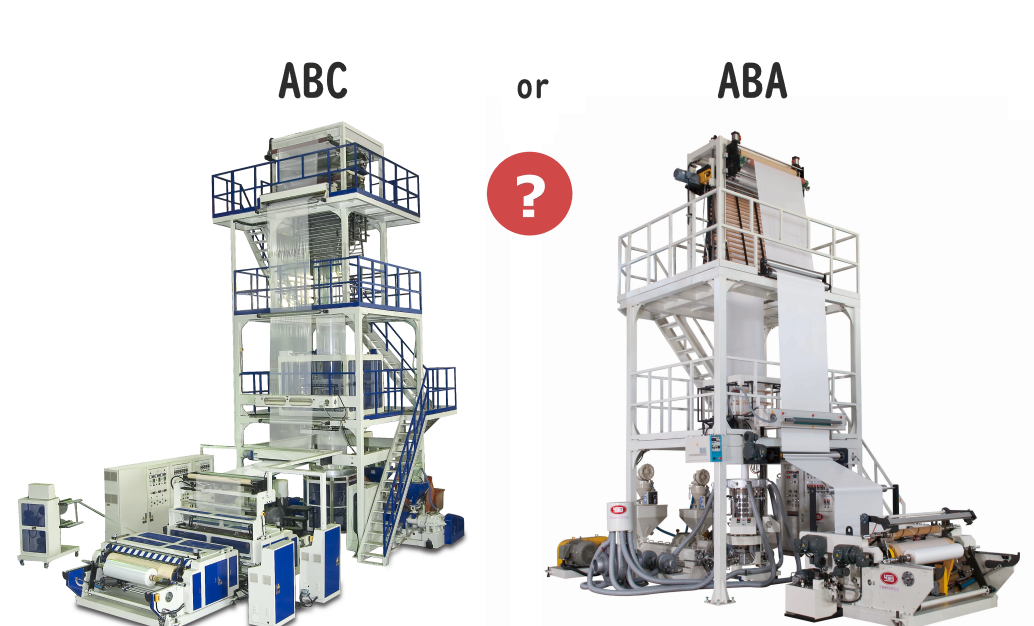

Both blown film lines of A-B-A and A-B-C can produce three-layer film but the main difference between them is the number of extruders and also the designs of flow channel. A-B-A consists of two extruders and A-B-C has three.

The A-B-A blown film production line is equipped with two extruders, extruder (A) is used for the outer and inner layers, and extruder (B) is used for the middle layer. This machine is often selected to reduce costs, such as adding recycled materials in the middle layer (B extruder) or adding CaCo³ (calcium carbonate) to increase weight because these plastic bags are mostly supplied to shopping malls and supermarkets, as grocery shopping bags. For the case of pricing by weight, the A-B-A blown film line is more effective in budget control.

The A-B-C blown film production line is equipped with three extruders, the proportion and material of each layer are controllable and selectable. In addition to making films with different colors from the outer and inner layers, different materials and proportion can also be used to make barrier layers, which can be used for vacuum packaging, waterproof packaging, food packaging and agricultural packaging, etc.