Product Consulting Cart

Your list is empty now

Add Products

Total : 0Unit

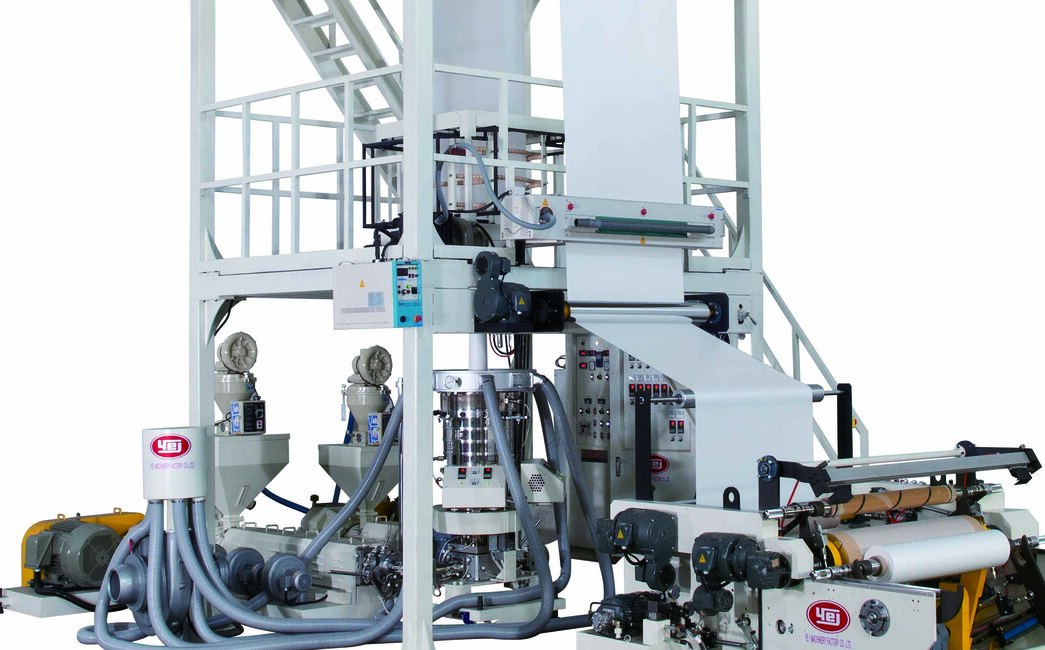

HSRT SERIES

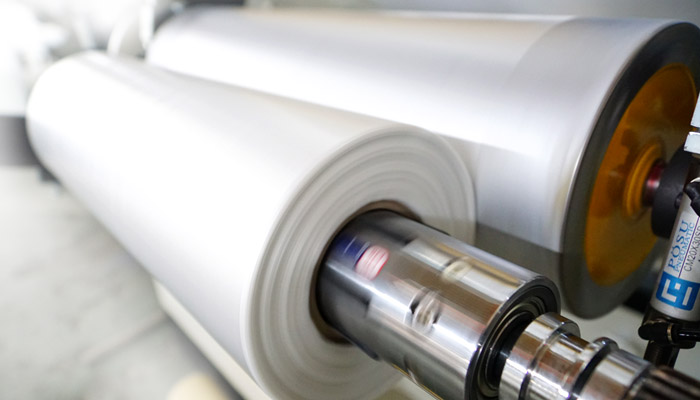

Multilayer Co-extrusion - PE Blown Film Machine

Material : HDPE/LDPE/LLDPE/BIODEGRADABLE MATERIAL

Screw Dia.: 45MM / 55MM / 65MM / 80MM

Thickness: 0.025~0.25MM

Extrusion Output : 120 ~ 250 kg/hr

No

Product

SPEC.

Image

HSRT-TR55

SCREW DIA. : 55 MM X3

EXTRUSION OUTPUT : 120~150 KG/HR

HSRT-TR55/65

SCREW DIA. : 55MM X2 + 65 MM X1

EXTRUSION OUTPUT : 150~200 KG/HR

HSRT-TR65/80

SCREW DIA. : 65MM X2 + 80 MM X1

EXTRUSION OUTPUT : 180~250 KG/HR

MODEL

HSRT SERIES

APPLICABLE MATERIAL

HDPE/LDPE/LLDPE/BIODEGRADABLE MATERIAL

FINAL PRODUCT

THREE LAYER FILM / FILM ROLLS

LAYFLAT WIDTH

600~2,300 M/M

THICKNESS RANGE

0.025~0.25MM

( Depending on material properties )

OUTPUT RANGE (KG / HR)

120 ~250 kg/hr

( Depending on size of die, film width, film thickness, working condition and material properties.)

COMPOSITION (STANDARD)

EXTRUDER, DRIVING MOTOR, CO-EXTRUSION DIE-HEAD, AIR-RING, FILTER, OSCILLATING TAKE-UP UNIT, CONTROL PANEL, EDGE POSITION CONTROLLER(EPC), WINDER

SCREW DIA.

Ø 45MM / Ø 55MM / Ø 65MM / Ø 80MM

SCREW/BARREL'S MATERIAL

ALLOY STEEL SACM-645

L/D RATIO

28/1 , 30/1 , 32/1

( Customized )

OPTIONS

AUTO LOADER, CORONA TREATOR, ROTARY DIE DEVICE, EMBOSSING ROLLER, TENSION CONTROL FOR WINDER, PRESSURE GAUGE, GRAVIMETRIC BLENDER, INTERNAL BUBBLE COOLING DEVICE, AUTO GAUGING CONTROL SYSTEM, BACK TO BACK WINDER, HOPPER DRYER, CPC, ETC.

【APPLICABLE MATERIALS】:

HDPE/LDPE/LLDPE/BIODEGRADABLE MATERIAL

【APPLICATION of multilayer films】:

Shopping bag, garbage bag, heavy-duty bag, shrink film, stretch wrap, multilayer bag, and so on.

• Production line with three extruders. (ABC blown film)

• Compact design, space-saving.

• Due to the different properties, we offer specific sets of die and air-ring. The blown film line is capable of running HDPE and LDPE by changing the insert.

• Extruder (3 units) :

With iron casting gear box (Three axles transmission type with SKF bearings), made of alloy steel with heat treatment and precise grinding. Solid, flexible, energy-saving, special spiral design to improve production capacity.

• A-B-C Die-head:

The specifications of the die-head are adjustable according to the difference in material properties and the thickness of final product.

• Melt Filter (3 sets) :

Filter impurities without leakage. We offer two(2) kinds of manual filters for selection. Hydraulic screen changer is available.

YE I has been engaged in the extrusion industry for more than 60 years. Combining our own design capabilities and production experience, we have purchased deep hole drilling machines and five-axis processing machines from Switzerland, Japan and Germany to be able to manufacture mechanical parts and key components in-house to ensure the overall quality and stable operation of the company's machines.

Air ring, die head, cylinder and extruder are the key components of blown film extrusion. With professional processing equipment, all processes are monitored by computer to ensure that every part of the blown film line is correctly manufactured without any possible human error.

About 200 sets of extrusion equipment are sold every year. YE I has already sold over ten thousand of blown film machines and other related equipment in 90 countries worldwide.

High quality

Easy operation

Low power consumption

Low CO2 emissions

Engaged in the plastic extrusion industry since 1960, over 10,000 units of YE I's blown film machines and recycling equipment have been sold to 120 countries, mostly in Europe, Asia and North America. Along with blown film extruders, plastic waste recycling equipment also been purchased to handle leftover bags. Thousands of best-selling ABA blown film extrusion lines have been installed for production. If you are looking for a trustworthy and innovative blown film line supplier, look no further than YE I MACHINERY!

Click "Read more" for more product information