Product Consulting Cart

Your list is empty now

Add Products

Total : 0Unit

YDN-W SERIES

Cooling Type : Water Cooled

Material : HDPE/LDPE/LLDPE/PP/EVA/ABS/PS/PLA/EPS/EPP

Screw Dia.: 65MM / 85MM / 100MM / 105MM / 120MM / 160MM

Output : 100 ~ 1,100 kg/hr

No

Product

SPEC.

Image

YDN-V65

OUTPUT : 100-150 KG/HR

SCREW DIA. : 65MM

YDN-V85

OUTPUT : 200-250 KG/HR

SCREW DIA. : 85MM

YDN-V100

OUTPUT : 380-450 KG/HR

SCREW DIA. : 100MM

YDN-V105

OUTPUT : 450-500 KG/HR

SCREW DIA. : 105MM

YDN-V120

OUTPUT : 550-700 KG/HR

SCREW DIA. : 120MM

YDN-V160

OUTPUT : 900-1100 KG/HR

SCREW DIA. : 160MM

MODEL

YDN-W SERIES

APPLICABLE MATERIAL

HDPE/LDPE/LLDPE/PP/EVA/ABS/PS/PLA/EPS/EPP

OUTPUT RANGE (KG / HR)

100~1100 kg/hr

( Depending on moisture content and percentage of contamination. )

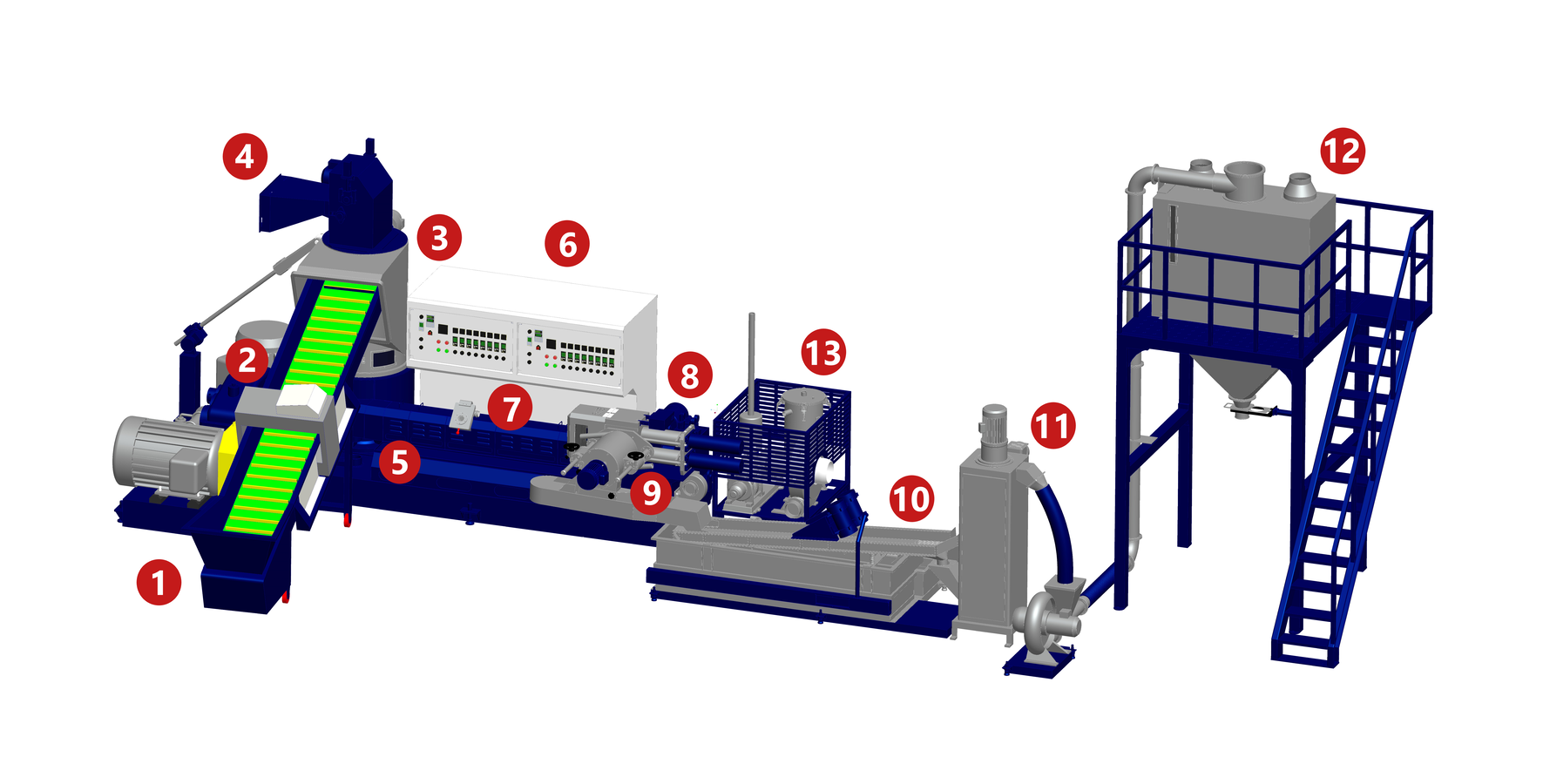

COMPOSITION (STANDARD)

FEEDING CONVEYOR, CUTTER COMPACTOR (SHREDDER),EXTRUDER, SCREEN CHANGER, PELLETIZER, VIBRATING DRYER, PELLETS COLLECTION SILO, CONTROL PANEL

SCREW DIA.

Ø 65MM / Ø 85MM / Ø100MM / Ø105MM / Ø120MM /Ø130MM /Ø160MM

SCREW/BARREL'S MATERIAL

ALLOY STEEL SACM-645

L/D RATIO

30/1 , 32/1

( Customized )

OPTIONS

NIP-ROLLER ( FOR FEEDING ), METAL DETECTOR, VACUUM PUMP, CENTRIFUGE,CHILLER, MASTERBATCH FEEDER, EXTRA VENTED HOLE

【APPLICABLE MATERIALS】:

HDPE, LDPE, LLDPE, PP, EVA, ABS, PS, PLA, EPS, EPP and so on.

【SUITABLE TYPES】:

Films (Roll, Stretch Film, Shrink Film, Multilayer Film), Bags (T-shirt Bag, Woven Bag and Jumbo bag),PP Fiber, PP Raffia, PP Silk, PP Yarn, etc.

• Direct combination of shredder, extruder and pelletizer.

• Die-face pelletizer.

• With venting hole. A vacuum pump is available as option.

• Twin hydraulic cylinder type screen changer - allows changing screen without machine shut-down.

• Control panel with PLC touch screen is available as option.

• Compact design, space-saving.

• High quality, moisture-free final products.

1. CONVEYOR (belt type):

Feed the material into the entrance of shredding drum. (It can be switched to manual or automatic mode according to actual needs.)

2. METAL DETECTOR (Optional):

If metal is detected during the feeding process, the safety mechanism will be activated, a warning sound will be issued and the conveyor will automatically stop.

3. SHREDDING DRUM:

Material will be fed into the shredder by the conveyor or nip-roller and be shredded by high-speed rotating blades.

4. NIP ROLLER (Optional) :

Used for the feeding of roll films.

5. EXTRUDER:

During this process, the material gradually melts and is thoroughly mixed and compacted.

6. CONTROL PANEL :

With PLC control is available as an option.

7. VENT PORT (single vented type):

Remove water and ink generated during melting. Extra vent port is available as an option.

8. HYDRAULIC SCREEN CHANGER:

Filter excess impurities and support the function of changing meshes without stopping the machine.

9. DIE-FACE PELLETIZER:

Granulation, the size of plastic particles can be adjusted during this process.

10. VIBRATING DRYER:

With the vibration mode to remove water/liquid, and at the same time it can help the particles to be guided to the particle size screening area.

11. CENTRIFUGE (optional):

Remove excess water on the surface of pellets.

12. PELLETS COLLECTION SILO:

Collect the pellets for subsequent bagging.

13. VACCUM PUMP (Optional):

With venting hole to evacuate air or vapor in materials. Mainly used for excess gas and liquid removal.

YE I has been engaged in the extrusion industry for more than 60 years. Combining our own design capabilities and production experience, we have purchased deep hole drilling machines and five-axis processing machines from Switzerland, Japan and Germany to be able to manufacture mechanical parts and key components in-house, such as screw, barrel, die head, filter, etc., to ensure the overall quality and stable operation of the company's machines.

About 200 sets of extrusion equipment are sold every year. YE I's professional high-quality recycling machines have been installed in 120 countries worldwide.

• YDE series - Forced Type Plastic Recycling Machine

• YDS series - Touch Screen Controlled Plastic Recycling Machine

• Two Stage Plastic Recycling Machine

Styrofoam box is recyclable

Plastic tableware is recyclable

Nets and fibers are recyclable

Films are recyclable

Plastic Waste Recycling

High quality

Easy operation

Low power consumption

Low CO2 emissions

Engaged in the plastic extrusion industry since 1960, with annual sales of 200 units extrusion equipment. YE I's best-selling high-quality plastic waste recycling line has been installed in 120 countries around the world to do the recycle and also dispose of leftover bags from blown film manufacturers. If you are looking for a reliable and innovative supplier of plastic recycling lines, YE I MACHINERY is undoubtedly your best choice!

Click "Read more" for more product information