Product Consulting Cart

Your list is empty now

Add Products

Total : 0Unit

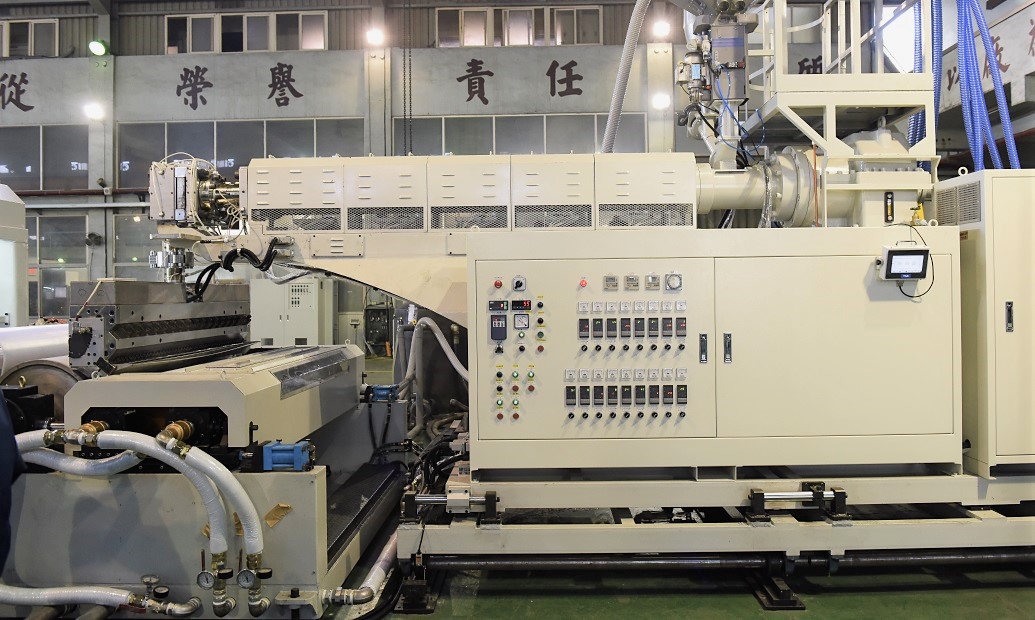

The Japanese customer's final product is disposable protective clothing for medical use. The thickness of the finished product after embossing should be at 0.12mm and the output must reach 120-150 kg/each hour. The additional requirement is that they need to recycle trimming material, so YE I has also set up an edge trimming (waste) recycling system for them. Its function is to roll in and crush the trimmed material, and send it back to the hopper above the extruder through a blower, without any waste. The formation of this kind of embossed film originally required the mixing of new materials and recycled materials, with trimming system, it forms a win-win cycle.

Considering that the barrel of extruder, screen changer and die-head need a certain amount of time for preheating, in order to allow the customer’s engineer to accurately start production at the scheduled time, YE I installed timers at each zone to ensure that the customer can set the preheating time in advance, all preheating procedures can be completed before production. As soon as the operator arrives, they can start production immediately, which helps to increase the production capacity of the day.

The most important thing in the process of making embossed film is the cooling. We designed a better cooling system for customers which equipped with 2.5" diameter water pipes, a stainless steel cooling tank placed between the chiller and the cooling roller, and a 5 HP water pump, finally increased the water pressure to 3.3 kg and the cool water flow rate increased by about 30~50%, it successfully enhanced the overall cooling capacity.

Through many years of experience, YE I knows very well how to make design adjustments in the simplest way, while also being able to meet custom requirements. The convenience of the machine, the improvement of efficiency and the simplification of operation have always been the focus of our consideration.