Product Consulting Cart

Your list is empty now

Add Products

Total : 0Unit

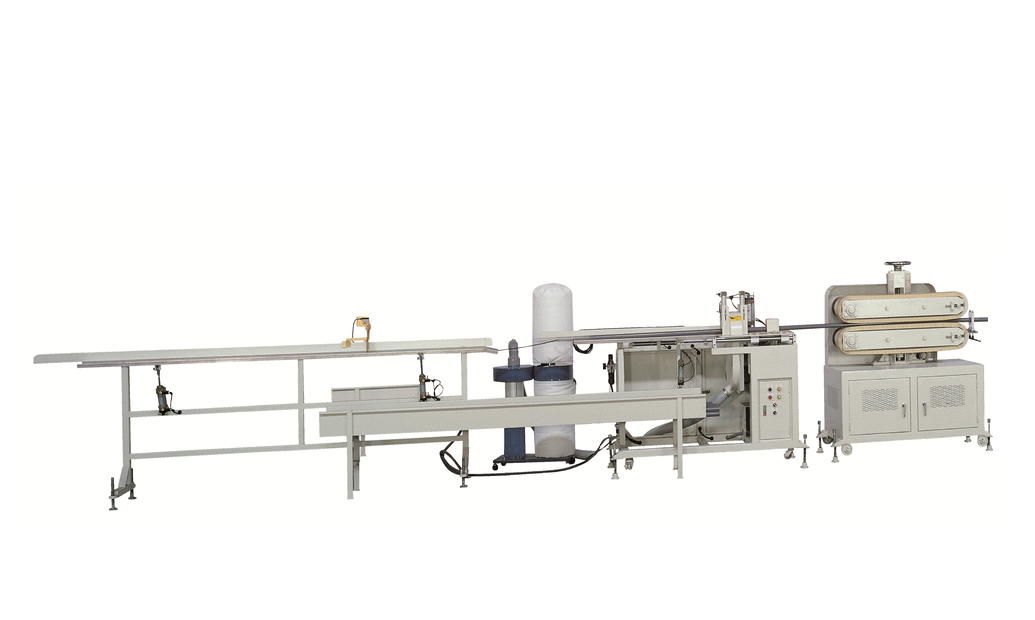

HP SERIES

PE/PVC Rigid Pipe Making Machine

Material : PE/PVC

Screw Dia.: 65MM / 100MM / 120MM

Pipe Dia: 1/2"~8"

Extrusion Output : 25 ~ 220 kg/hr

No

Product

SPEC.

Image

HP-45

SCREW DIA. : 45 MM

EXTRUSION OUTPUT : 25~40 KG/HR

HP-55

SCREW DIA. : 55 MM

EXTRUSION OUTPUT : 25~50 KG/HR

HP-65

SCREW DIA. : 65 MM

EXTRUSION OUTPUT : 30~80 KG/HR

HP-80

SCREW DIA. : 80 MM

EXTRUSION OUTPUT : 60~105 KG/HR

HP-100

SCREW DIA. : 100 MM

EXTRUSION OUTPUT : 70~150 KG/HR

HP-120

SCREW DIA. : 120 MM

EXTRUSION OUTPUT : 120~220 KG/HR

MODEL

HP SERIES

APPLICABLE MATERIAL

PE / PVC

FINAL PRODUCT

PE / PVC RIGID PIPES

PIPE DIAMETER

1/2"~ 8"

(Depending on the material properties.)

OUTPUT RANGE (KG / HR)

25 ~220 kg/hr

( Depending on size of die, pipe diameter, working condition and material properties.)

COMPOSITION (STANDARD)

EXTRUDER, FILTER, DIE, CALIBRATION UNIT, HAUL-OFF UNIT, CUTTING UNIT, COLLECTION STACK FOR PIPE

SCREW DIA.

Ø 45MM / Ø 55MM / Ø 65MM / Ø 80MM /Ø 100MM / Ø 120MM

( Available types : Single screw or Twin screw )

SCREW/BARREL'S MATERIAL

ALLOY STEEL SACM-645

L/D RATIO

22/1

OPTIONS

【APPLICABLE MATERIALS】:

PE / PVC

1. Variable diameters are available to expand production.

2. Easy to operate and maintain.

3. Great mechanical safety and long service life.

• Extruder :

The screw and barrel of the main extruder are made of high-quality alloy steel, hard chrome plated, nitrided and polished. The special screw design can achieve optimal mixing and eliminate the carbonization (burning) of PVC materials.

• Die-head :

1. Made of high-grade alloy steel, hard chrome plated to ensure maximum wear resistance.

2. Torpedo design, wider flow channel reduces back pressure, increases output and improves product quality.

3. By changing the die insert and the vacuum sizing sleeve (calibration), the same die-head can be used to manufacture pipes with different diameters within a certain range.

• Vacuum calibrating spray/cooling tank :

1. Both spray tank and cooling tank are made from stainless steel. Vacuum pump, water pump, circulation pump are included.

2. A large number of nozzles are used to obtain the maximum cooling efficiency, and the vacuum system precisely controls the size of pipes.

• Haul-off unit and cutter :

1. Multi-block caterpillar type haul-off unit with AC motor drive system for precision pulling.

2. Traveling hacksaw cutter cuts the pipe pneumatically according to the length preset by the digital counter.

YE I has been engaged in the extrusion industry for more than 60 years. Combining our own design capabilities and production experience, we have purchased deep hole drilling machines and five-axis processing machines from Switzerland, Japan and Germany to be able to manufacture mechanical parts and key components in-house to ensure the overall quality and stable operation of the company's machines.

Die head, cylinder and extruder are the key components of film making extrusion. With professional processing equipment, all processes are monitored by computer to ensure that every part of the blown film line is correctly manufactured without any possible human error. About 200 sets of extrusion equipment are sold every year.

High quality

Easy operation

Low power consumption

Low CO2 emissions